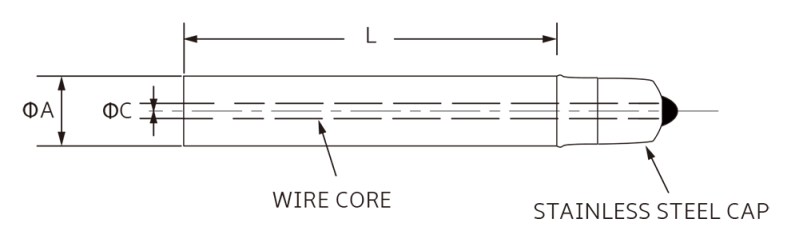

Aluminum Water Heater Anode Rod with Stainless Steel Cap

One of the most common killers of water heater is interior corrosion. The water inside the heater tank contains many destructive properties including heat and harsh minerals that can build up and eat away at the steel sidings, shortening the life of the electric water heater.

Anode rod is the key factor in preventing corrosion and leaks in water heater. The anode rod delivers electrons into the water that helps to create an environment that diverts corrosive action away from the tank walls to the anode rod. Thus, it prolongs the service life of the inner tank and the heating pipe.

Our aluminum extruded anode rod has high surface and length ratios in relation to cross-sectional area. It allows to deliver a greater amount of current per weight than usual cast anode. With the lowest voltage during the sacrificial process, aluminum anode rods usually corrode at a slower rate than magnesium rods. Thus, aluminum anode rods are the least expensive alternative, especially for water heater that heats up hard water. The anode rod should be replaced when the corrosion has eaten approximately 75% of the rod’s mass. Generally, our anode rod is expected to provide about 2 years of corrosion protection.

Description

—— Chemical Composition ——

Parameters

| Category | Water Heater Anode |

|---|---|

| Substrate | Aluminum Alloy |

| Shape | Rod |

| Applicable Environment | Fresh Water |

| Application | Water Heater |

| Certification | ABS |

Specification

Specification

Note: The anode rod length can be customized upon request.