Heat Treater Aluminum Anode Rod

Casted from high-voltage and high-potential alloy, our aluminum anode is designed to meet the standard GALVALUM III, containing nominal amounts of indium, zinc, and silicon. It has a proven track record for delivering superior cathodic protection for any type of structure requiring a compact solution in highly corrosive saltwater/brines with elevated temperatures. It is typically applied in heater treaters, heat exchangers, salt water storage tanks, oilfield tanks, skimmers, oil-separation vessels, pressure vessels and other production vessels.

Description

Casted in low-iron, high-purity alloys, our aluminum anodes are designed as per the standard below:

—— Electrochemical Properties ——

Aluminum anodes have a much slower consumption rate in severe environment conditions including high acidity or in the presence of chlorine or oxygen.

—— Practical Application ——

This anode can be assembled with high compression molded fiberglass anode mount caps (blue or red). The red one can be installed in standard 4” SCH 40 fittings with grooved couplings. The blue one can be used for mounting in standard 4” SCH 80 fittings with grooved couplings.

Parameters

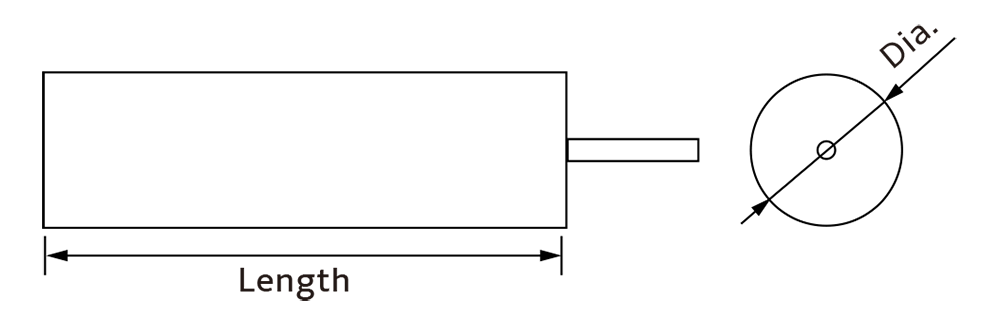

| Category | Heat Treater Anode |

|---|---|

| Substrate | Aluminum Alloy |

| Shape | Rod |

| Applicable Environment | Brackish Water |

| Application | Heater Treater |

| Certification | DNV |

Specification

Specification

Note: All dimensions and weights shown above are nominal. The information provided is subject to change without notice.